Resin Art Safety Guidelines: Your Complete Guide

The mesmerizing swirls of color, the glass-like finish, and the endless creative possibilities have made resin art one of recent years’ most popular crafting mediums. From stunning river tables to delicate jewelry pieces, resin transforms ordinary objects into extraordinary works of art. However, beneath the beautiful finished products lies a critical truth: working with resin involves handling industrial chemicals that demand respect and proper safety protocols.

This comprehensive guide serves as your essential resource for resin art safety and home resin safety. Whether you’re a beginner picking up your first epoxy bottle or an intermediate artist looking to refine your safety practices, this guide will empower you to create beautiful resin art while protecting your health, family, and environment. We’ll cover everything from understanding the chemical risks and selecting proper protective equipment to setting up a safe workspace, handling materials correctly, disposing of waste responsibly, preparing for emergencies, and protecting yourself from long-term health effects like chemical sensitization resin.

By following these guidelines for safe resin crafting, you can confidently pursue your artistic passion, knowing you’re taking the necessary steps to minimize risks and create responsibly.

Understanding the Unseen: Chemical Hazards in Common Craft Resins

What Are You Working With? A Look at Resin Chemistry

When you open those resin and hardener bottles, you’re not just working with art supplies but handling reactive chemical compounds. Craft resins, whether epoxy, UV-curing, or polyurethane varieties, undergo chemical reactions to transform from liquid to solid. While creating the durable finish we love, this curing process involves components that can pose serious health risks. The uncured components – resin and hardener or catalyst – are the primary source of hazards in resin art.

Key Chemical Hazards in Resins: Know Your Enemy

Understanding resin chemical hazards is the first step in protecting yourself. Here are the main risks you face when working with uncured resin:

Skin and Eye Irritants/Corrosives: Liquid resin components, particularly hardeners used in epoxy systems, can cause immediate irritation or chemical burns upon contact with skin or eyes. Amine-based hardeners are especially corrosive and can cause severe burns within minutes of contact.

Sensitizers (Allergens): This is the most insidious risk in resin work. Many resin components are potent sensitizers, including:

- Epoxy resins and their amine hardeners

- Isocyanates found in polyurethane resins

- Acrylates in UV-curing resins

Sensitization means your immune system develops an allergic response to the chemical. Once sensitized, you’ll experience allergic reactions with every exposure, often becoming more severe over time. This condition is typically permanent and can end your ability to work with resins.

Volatile Organic Compounds (VOCs): VOCs in resin are chemicals that evaporate at room temperature, creating fumes you can inhale. Even products labeled “low-VOC” or “no-VOC” may release vapors during mixing, pouring, and curing. These can cause:

- Respiratory irritation

- Headaches and dizziness

- Nausea

- Long-term organ damage with chronic exposure

Polyester and some polyurethane resins typically have higher VOC content and more pungent odors than epoxy resins.

Specific Components of Concern:

- Epoxy Resins: Often contain bisphenol A (BPA) derivatives, epichlorohydrin, and various amine hardeners that are skin sensitizers and respiratory irritants

- Polyurethane Resins: Contain isocyanates (MDI, TDI), which pose significant respiratory risks and are potent sensitizers

- UV Resins: Contain acrylates and photoinitiators that can cause severe skin sensitization and eye damage

Flammability: While many epoxy base resins aren’t highly flammable, the solvents (like alcohol inks or acetone for cleanup) can be extremely flammable. Additionally, polyurethane resins can decompose in fire to create highly toxic gases, including hydrogen cyanide.

Dust from Sanding: Never underestimate the hazards of resin dust. Sanding cured or partially cured resin creates fine particles that can be inhaled and may contain unreacted hazardous components. This dust can cause respiratory irritation and contribute to sensitization.

The Importance of Safety Data Sheets (SDS)

Every resin product comes with a Safety Data Sheet (SDS), and understanding resin SDS documents is crucial for your safety. An SDS is a standardized document that provides comprehensive information about chemical hazards and safe handling procedures.

Before using any resin product:

- Obtain the SDS from the manufacturer (usually available on their website)

- Please read it thoroughly before opening the product.

- Pay special attention to these sections:

- Section 2: Hazards Identification

- Section 4: First Aid Measures

- Section 8: Exposure Controls/Personal Protection

- Section 13: Disposal Considerations

- Keep SDS documents accessible in your workspace for emergency reference.

Your Non-Negotiable Shield: Essential Personal Protective Equipment (PPE) for Resin Art

Why PPE is Non-Negotiable for Safe Resin Crafting

Personal Protective Equipment (PPE) forms the critical barrier between you and resin chemical hazards. It isn’t optional or something you can skip “just this once.” PPE must be worn every time you work with resin, from when you open the bottles until cleanup.

Important: Products labeled as “non-toxic” when cured still contain hazardous chemicals in their liquid state. “Non-toxic” labels on cured products do NOT mean PPE isn’t needed for liquid components.

Respiratory Protection: Breathing Safely

Why you need a respirator: Resin releases fumes and VOCs throughout the working process—during measuring, mixing, pouring, applying heat, and during the curing period, these invisible vapors can cause immediate irritation and long-term health damage.

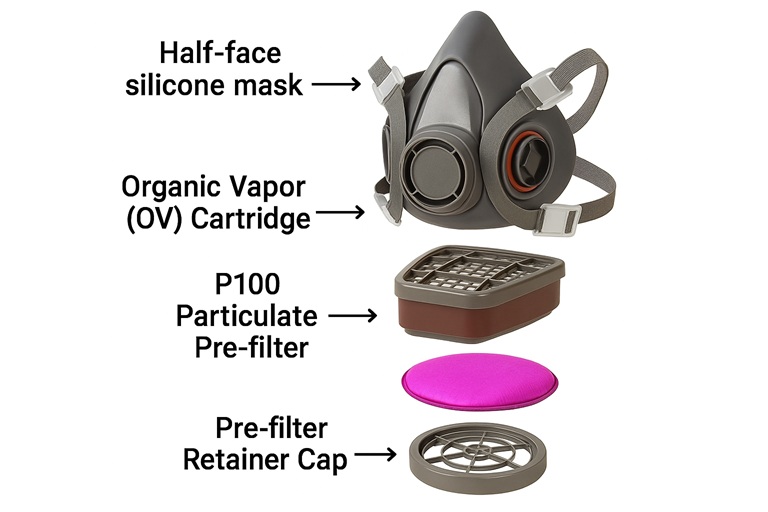

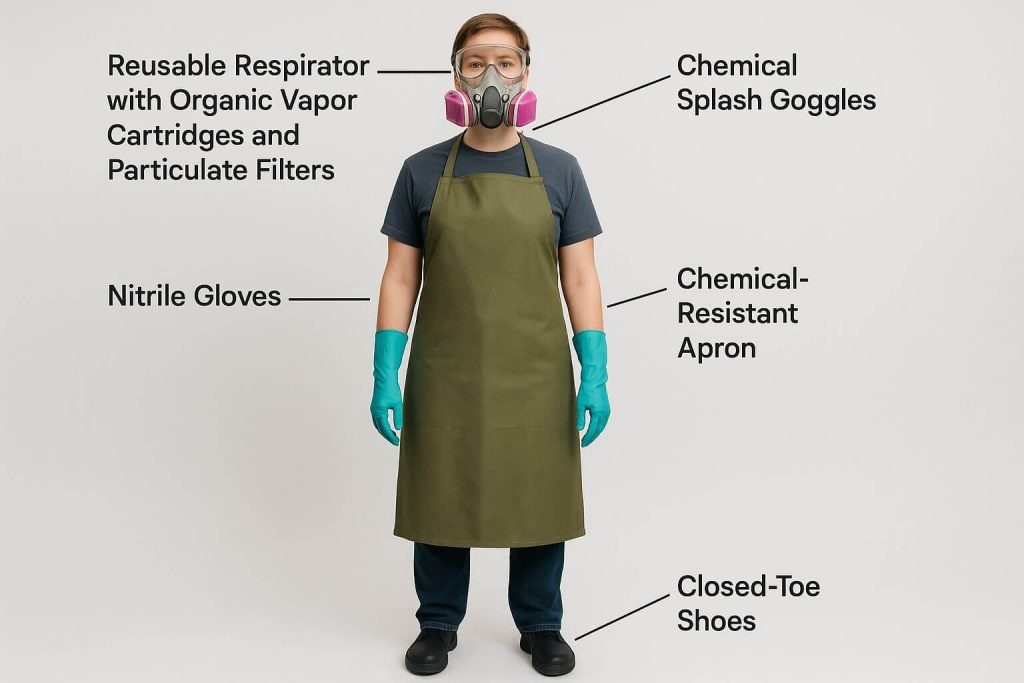

Respirator Selection (Resin Respirator Selection): Your respiratory protection must meet specific standards:

- Use a NIOSH-approved reusable half-face or full-face respirator.

- Equip it with organic vapor (OV) cartridges, which are essential for filtering resin fumes.

- Add P95 or P100 particulate pre-filters to your OV cartridges, especially if you’ll be sanding or if your work might generate aerosols.

- For polyurethane resin safety tips, Isocyanates require special consideration. While industrial settings might use supplied air systems for home use, the best air-purifying respirator with OV/P100 combination is critical.

Correct Fit and Seal: A respirator only works if it seals properly to your face. Every time you put it on:

- Perform a negative pressure check: Cover the filters and inhale gently – the mask should collapse slightly

- Perform a positive pressure check: Cover the exhalation valve and exhale gently – no air should leak around the edges

- Facial hair prevents proper sealing – you must be clean-shaven where the respirator contacts your face

Cartridge Maintenance and Replacement:

- Replace cartridges based on manufacturer guidelines (usually after 40 hours of use or 30 days after opening, whichever comes first)

- If you detect ANY odor while wearing your respirator, replace the cartridges immediately (though note that some chemicals have no odor)

- Store your respirator in a sealed bag or container between uses.

- Never wash cartridges – moisture destroys their effectiveness.

Hand Protection: Choosing the Right Gloves

Why gloves are essential: Your hands are most likely to contact liquid resin, and skin exposure is the primary route for irritation and sensitization.

Glove Material:

- I strongly recommend nitrile gloves for resin work, especially with epoxy and UV resins. Nitrile provides excellent chemical resistance.

- For extended exposure or when working with polyurethane resins, consider butyl rubber gloves for superior protection.

- NEVER USE LATEX GLOVES – they provide inadequate chemical protection and can cause allergic reactions

Glove Thickness and Cuff Length:

- Choose gloves at least 4-6 mil thick for better protection

- Extended cuff gloves protect your wrists and forearms

- Consider double-gloving for extensive work sessions

Proper Use:

- Put gloves on before handling any resin materials

- Remove gloves by turning them inside out to avoid skin contact with contaminated surfaces

- Never reuse disposable gloves – they’re single-use only

- Change gloves immediately if torn or contaminated

- Wash hands thoroughly after removing gloves

Eye Protection: Guarding Your Sight

Why it’s crucial: Resin and hardener splashes can cause severe eye damage, including permanent vision loss. Even tiny droplets can cause serious injury.

Types of Eye Protection:

- Chemical splash goggles (indirectly vented) provide the best protection with a complete seal around your eyes

- Safety glasses with side shields (ANSI Z87.1 certified) are the absolute minimum

- A full-face respirator provides both respiratory and eye protection in one unit

Protective Clothing: Covering Up

Your resin PPE ensemble must include appropriate clothing:

- Wear long-sleeved shirts and long pants – no exposed skin

- A chemical-resistant apron or disposable coveralls (like Tyvek suits) offer superior protection

- Closed-toe shoes are mandatory – no sandals or open-toed footwear

- Consider disposable shoe covers to prevent tracking resin through your home

- Hair ties or caps to keep hair away from resin

The goal is to eliminate any possibility of skin contact with resin materials.

PPE Care, Maintenance, and Disposal

- Clean reusable respirators (not the cartridges) with mild soap and water after each use

- Store all PPE in a clean, dry location away from resin work areas

- Dispose of contaminated disposable PPE in sealed bags

- Never attempt to clean and reuse disposable gloves or filters

Creating a Safe Resin Art Zone at Home

The Importance of a Dedicated and Prepared Workspace

Creating a safe resin workspace is fundamental to protecting your health and home. Your resin work area should be:

- Separated from living spaces, especially kitchens and bedrooms

- Easy to clean with non-porous surfaces

- Well-organized to prevent accidents

- Secured against unauthorized access

Ventilation, Ventilation, Ventilation! (Resin Ventilation at Home)

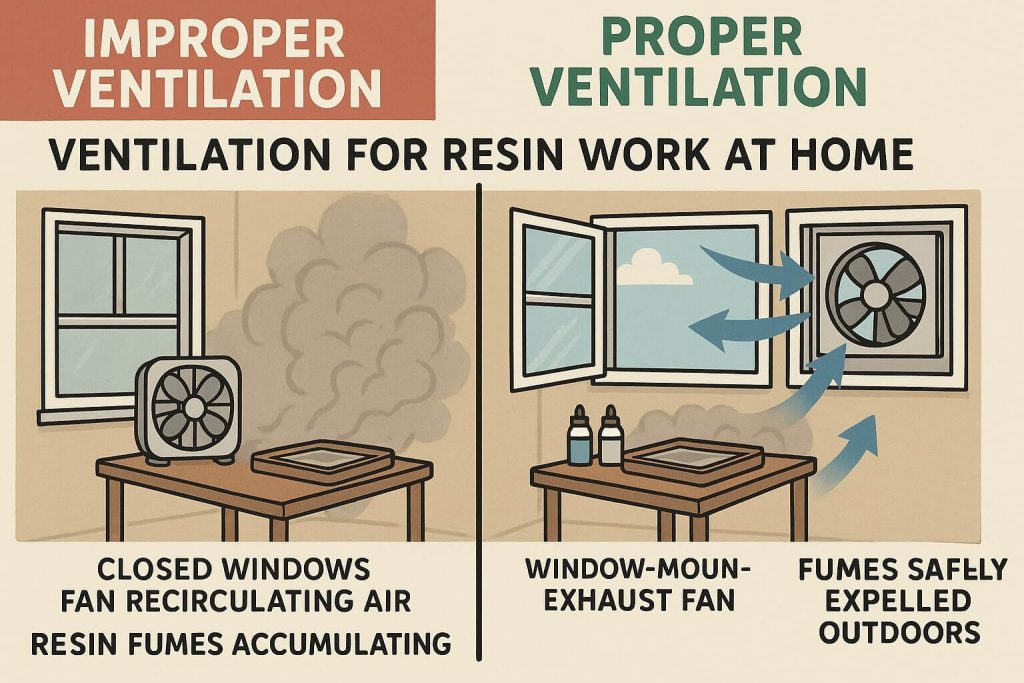

Why it’s paramount: Proper ventilation removes hazardous fumes, reduces VOC concentration, and is your primary environmental control against respiratory exposure. Ventilation is NOT optional – it’s essential for every resin session.

Natural Ventilation:

- Open windows on opposite sides of your workspace to create cross-ventilation

- Position a box fan in one window blowing OUT to exhaust fumes

- Open doors between the workspace and outdoors when possible

- Work near open garage doors if using a garage workspace

Mechanical Ventilation (DIY Resin Fume Extraction):

- Install a window-mounted exhaust fan rated for the room size

- Position your work table near the exhaust fan

- Consider building a ventilated enclosure with an inline duct fan venting outside

- For serious hobbyists, a proper fume hood vented to the exterior provides optimal protection

Critical warning: Fans that recirculate air within the room (ceiling fans, portable fans, standard air conditioners) do NOT have adequate ventilation for resin fumes. You need active exhaust to the outside.

Air Purifiers: HEPA filters with activated carbon can supplement your ventilation system but cannot replace proper exhaust ventilation and PPE. They may help with odor but don’t eliminate the need for respiratory protection.

Surface Protection and Organization

- Cover work surfaces with silicone mats, plastic sheeting, or parchment paper

- Ensure your work surface is perfectly level – resin self-levels and will flow to low spots

- Organize all materials within arm’s reach before starting

- Keep paper towels and cleaning supplies readily accessible

- Store resin and hardener in original containers, tightly sealed, clearly labeled

- Keep all chemicals away from heat sources and direct sunlight

Environmental Controls: Temperature and Humidity

Temperature: Most resins work best between 20-25°C (68-77°F)

- The cold resin becomes thick and difficult to work with

- Hot conditions accelerate curing and reduce working time

- Extreme temperatures can prevent proper curing

Humidity:

- High humidity can cause amine blush (cloudy surface) on epoxy

- Polyurethane resins are susceptible to moisture

- Use a dehumidifier in humid conditions

- Monitor conditions with a digital thermometer/hygrometer

Securing the Area: Protecting Children, Pets, and Vulnerable Individuals

This section is critical – lives depend on it.

Protecting family from resin fumes requires absolute vigilance:

- Install locks on workspace doors

- Never allow children or pets in the workspace during resin use OR throughout the entire curing period

- Store all materials in locked cabinets or high shelves

- Even cured resin scraps can be choking hazards for children and pets

- Post clear warning signs when the resin is curing

- Educate all household members about the dangers

- Consider working only when children are at school or sleeping

Safe Handling Protocols: From Start to Finish

Preparation is Key: Before You Begin

Before opening any resin products:

- Read all product instructions and review the SDS

- Set up your ventilation system

- Lay out all necessary tools and materials

- Put on ALL your resin PPE – respirator, gloves, eye protection, protective clothing

- Ensure your workspace is secure from children and pets

- Have cleaning supplies and first aid materials ready

Safe Measuring, Mixing, and Pouring Resin

Accurate Ratios: Incorrect mixing ratios can result in:

- Uncured sticky resin that remains hazardous

- Excessive heat generation

- Poor final properties

Follow these safe resin mixing and pouring guidelines:

- Measure precisely by volume or weight as specified by the manufacturer

- Use separate, clearly marked containers for Part A and Part B

- Pour hardener into resin (not vice versa) to minimize splashing

Mixing Techniques:

- Mix slowly but thoroughly for 3-5 minutes minimum

- Scrape the sides and bottom of the container repeatedly

- Avoid whipping air into the mixture

- Consider the two-cup method: Mix in one cup, transfer to a second clean cup, mix again

- Be aware of pot life – the working time before resin begins to cure

Temperature Considerations:

- Slightly warming resin (in a warm water bath with unopened bottles) reduces viscosity

- Never add water to resin or allow water contamination

- Be aware that larger volumes generate more heat during curing

Using Heat Tools Safely for Bubble Removal

Heat Guns:

- Generally safer than torches (no open flame)

- Keep the heat gun moving constantly

- Maintain a 6-8 inches distance from the resin surface

- Don’t overheat – this can cause yellowing or premature curing

Torches (Butane/Propane):

- Use with extreme caution

- Quick passes only – 2-3 seconds maximum

- Keep the flame moving constantly

- There is a high risk of scorching resin, melting molds, or starting fires

- Never use near flammable materials

- Have a fire extinguisher accessible

Always wear full PPE when using heat tools; heating can increase fume release.

Resin Curing Safety Guidelines

Understanding resin curing safety guidelines protects you during the full curing cycle:

- Off-gassing continues throughout the cure (typically 24-72 hours)

- Maintain ventilation for the entire curing period

- Cover curing pieces to protect them from dust while ensuring airflow

- Large pieces generate significant heat – monitor for overheating

- Keep the curing area completely secured from children and pets

- Post warning signs indicating resin is curing

- Don’t assume resin is safe to handle just because it feels dry to touch

Preventing Accidental Contamination

- Establish a no food or drink policy in your resin workspace

- Never eat, drink, smoke, or apply cosmetics while working

- Don’t touch your face with gloved hands

- Change gloves if you must touch clean surfaces

- Remove contaminated clothing before leaving the workspace

- Wash hands thoroughly with soap and water after work

- Never use solvents to clean resin from the skin – this drives chemicals deeper

- Consider having dedicated “resin work” clothes that stay in the workspace

After the Art: Responsible Cleanup and Safe Resin Disposal

Cleaning Tools and Equipment Safely

Clean tools while resin is still liquid – it’s much easier and safer:

- Wipe excess resin with paper towels

- Clean with isopropyl alcohol (90%+) or acetone

- Work in a well-ventilated area

- Wear full PPE during cleanup

- For silicone tools, you can let the resin cure and peel it off

Never pour solvent-resin mixtures down the drain – this is illegal and environmentally harmful.

Managing Spills Effectively

For uncured resin spills:

- Don PPE immediately

- Contain the spill with paper towels or absorbent material

- Scoop up liquid with cardboard or plastic scrapers

- Absorb residue with kitty litter or commercial spill absorbent

- Clean the area with an appropriate solvent

- Dispose of all contaminated materials as hazardous waste

For cured spills:

- It may require scraping or sanding

- Always wear respiratory protection when generating dust

- Vacuum with HEPA filter if available

- Dispose of dust and chips as solid waste

Safe Handling and Storage of Solvents (e.g., Isopropyl Alcohol)

Solvents used for resin cleanup require careful handling:

- Store in original containers with tight-fitting lids

- Label all containers clearly

- Keep in a cool, well-ventilated area

- Store away from heat sources and ignition sources

- Never store in food or drink containers

- Keep separate from oxidizers and acids

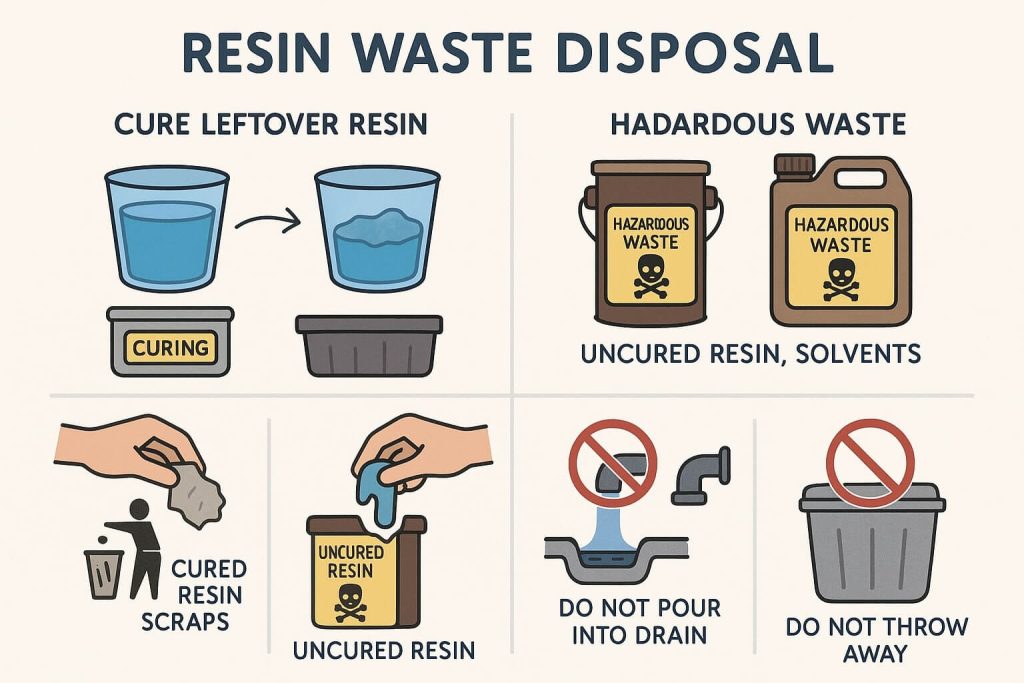

Disposing of Resin Waste: The Right Way

Safe resin disposal protects our environment and complies with regulations:

Uncured/Liquid Resin:

- NEVER pour down drains or place in household trash

- Best option: Mix leftover Part A and Part B in correct ratios, allow to cure, then dispose of as solid waste fully

- For unmixed components: Take to a Household Hazardous Waste (HHW) facility

- Never pour on the ground or in storm drains

Cured Resin Scraps:

- Fully cured resin is generally considered non-hazardous

- It can usually be disposed of in regular household trash

- Check local regulations for specific requirements

- Be mindful of sharp edges that could injure waste handlers

Empty Resin Containers:

- Drain as completely as possible (less than 3% residue)

- Some areas allow recycling if thoroughly empty

- If significant residue remains, treat it as hazardous waste

- Consider curing residue inside containers before disposal

Contaminated Supplies:

- Allow resin on gloves, stir sticks, and wipes to cure fully

- Once cured, it is usually acceptable in regular trash

- Heavily saturated items that can’t be cured go to the HHW facility

- Never burn resin-contaminated materials

Solvent Waste (containing dissolved resin):

- This is hazardous waste requiring special disposal

- Never pour down drains or evaporate large amounts

- Store in labeled containers for HHW collection

- Some areas have solvent recycling programs

ALWAYS CHECK LOCAL MUNICIPAL WASTE DISPOSAL REGULATIONS – requirements vary significantly by location.

Emergency Preparedness: Resin First Aid Guide

General First Aid Principles for Chemical Exposure

When dealing with resin exposure, every second counts:

- Remove the person from the source of exposure immediately

- Remove contaminated clothing and jewelry

- Have emergency numbers posted visibly (Poison Control: 1-800-222-1222 in the US)

- Bring the product SDS to medical personnel

- Never delay seeking professional help for severe exposures

Skin Contact with Resin

Immediate actions:

- Remove contaminated clothing and jewelry

- Wash the affected area with soap and warm water for at least 15 minutes

- DO NOT use solvents on skin – they increase absorption

- Pat dry gently (don’t rub)

- If irritation persists or burns appear, seek medical attention

- Watch for delayed reactions over the next 24-48 hours

Eye Exposure to Resin

This is a medical emergency requiring immediate action:

- Flush eyes immediately with clean, lukewarm water for at least 15-20 minutes

- Hold eyelids open to ensure thorough flushing

- Remove contact lenses if possible after initial flushing

- Continue flushing while someone calls for emergency medical help

- Seek IMMEDIATE medical attention for ANY eye exposure

- Bring the resin SDS to the medical facility

Inhalation of Resin Fumes

Response to vapor inhalation:

- Move to fresh air immediately

- Loosen tight clothing

- If breathing is difficult, sit upright

- If symptoms persist (coughing, wheezing, chest tightness), seek medical attention

- If breathing stops, call 911 and begin CPR if trained

- Be alert for delayed symptoms, especially with isocyanate exposure

Ingestion of Resin

If you swallowed resin

- Call Poison Control or emergency services immediately

- DO NOT induce vomiting unless specifically instructed

- Rinse mouth with water (don’t swallow)

- Never give anything by mouth to an unconscious person

- Provide the SDS to emergency responders

When to Seek Immediate Professional Medical Help

Seek emergency medical care for:

- Any eye exposure to resin or hardener

- Difficulty breathing or persistent respiratory symptoms

- Severe skin reactions or chemical burns

- Loss of consciousness

- Persistent nausea, dizziness, or headache

- Any exposure in pregnant women

- When advised by Poison Control

Resin Art in a Shared Home: Protecting Others

Preventing Cross-Contamination in Living Spaces

Maintaining strict boundaries between resin work and living spaces is essential:

- Never bring resin tools or materials into the kitchen or food prep areas

- Don’t use household items (measuring cups, utensils) for resin work

- Keep dedicated cleaning supplies that never leave the resin area

- Change clothes and shoes before entering living spaces

- Wash hands thoroughly before touching common surfaces

Protecting Vulnerable Household Members (Children, Pets, Sensitive Individuals)

Resin health risks are significantly higher for:

- Children (developing bodies, tendency to put things in mouths)

- Pets (can’t understand warnings, may lick surfaces)

- Pregnant women (potential developmental risks)

- People with asthma or respiratory conditions

- Individuals with compromised immune systems

Protection strategies:

- Schedule resin work when vulnerable individuals are away

- Use additional barriers (baby gates, closed doors)

- Consider working in a detached garage or shed

- Never rely on “they won’t go in there” – use physical barriers

- Educate older children about dangers without creating fear

Managing Fume and Dust Migration Throughout the Home

Vapors and dust don’t respect room boundaries:

- Seal gaps under doors with draft stoppers

- Use plastic sheeting to create temporary barriers

- Run exhaust ventilation to create negative pressure in the work area

- Change clothes before moving through the house

- Use a HEPA vacuum for cleanup (regular vacuums spread fine particles)

- Consider the HVAC system – close vents in the resin room to prevent circulation

Maintaining Indoor Air Quality

Protecting your home’s air quality requires ongoing vigilance:

- Monitor VOC levels with a detector if working frequently

- Schedule resin work based on household activities

- Allow extra curing time before bringing pieces into living spaces

- Communicate clearly with household members about work schedules

- Consider professional air quality testing if doing extensive resin work

- Install carbon monoxide detectors (some curing reactions can produce CO)

The Hidden Danger: Understanding and Preventing Chemical Sensitization from Resin

What is Chemical Sensitization?

Chemical sensitization resin represents one of resin art’s most serious long-term risks. Sensitization occurs when your immune system develops an allergic response to resin components. Once sensitized, this reaction is typically permanent, and future exposures to even microscopic amounts can trigger severe symptoms. This can effectively end your ability to work with resins or even be near them.

How Does Resin Sensitization Develop?

Sensitization isn’t immediate – it develops through:

- Repeated skin contact with uncured resin or hardener

- Chronic inhalation of vapors

- Exposure to resin dust from sanding

- Contact with contaminated surfaces or tools

The timeline varies dramatically:

- Some people sensitize within days or weeks

- Others work for years before developing sensitivity

- Individual susceptibility varies based on genetics and overall health

- There’s no way to predict who will become sensitized or when

Common Symptoms of Resin Sensitization

Skin Reactions (Allergic Contact Dermatitis):

- A red, itchy rash that may spread beyond the contact area

- Blistering is similar to poison ivy

- Dry, cracking, or peeling skin

- Swelling and inflammation

- Reactions often worsen with each exposure

Respiratory Symptoms:

- Asthma-like symptoms (wheezing, chest tightness)

- Persistent cough

- Shortness of breath

- Reactions can occur even from trace amounts in the air

Eye Symptoms:

- Redness and irritation

- Excessive tearing

- Swelling of eyelids

- Light sensitivity

Severe Reactions: While rare, anaphylaxis (life-threatening allergic reaction) can occur in sensitized individuals.

Long-Term Prevention: Your Best Defense Against Resin Allergies

Preventing resin allergies requires absolute commitment to safety:

Minimize ALL Exposure:

- Treat every drop of uncured resin as a sensitization risk

- Use complete PPE every single time – no exceptions

- Maintain scrupulous cleanliness in your workspace

- Never become complacent, even after years without problems

Work Habits That Prevent Sensitization:

- Double-check PPE fit before each session

- Change gloves frequently

- Never touch your face during work

- Clean up spills immediately

- Wash hands thoroughly, even after wearing gloves

- Shower after extensive resin work

Environmental Controls:

- Maintain excellent ventilation always

- Use local exhaust when possible

- Keep workspace humidity controlled

- Regular deep cleaning of all surfaces

What If You Suspect You’ve Become Sensitized?

If you experience any allergic symptoms:

- Stop using resin products immediately

- Document your symptoms with photos and notes

- See a dermatologist or allergist promptly

- Request patch testing for specific resin components

- If confirmed sensitized, you must avoid all future exposure

- Inform your doctor about all resin types you’ve used

Remember: Continued exposure after sensitization will worsen reactions and could lead to life-threatening situations.

Quick Safety Checklist for Every Resin Session

Before You Begin:

- ✓ Workspace ventilation running

- ✓ All PPE ready and in good condition

- ✓ Respirator seal check completed

- ✓ Fresh gloves ready (plus extras)

- ✓ Eye protection is clean and fitted

- ✓ Protective clothing on

- ✓ Work area secured from children/pets

- ✓ Emergency numbers posted

- ✓ First aid supplies accessible

- ✓ SDS sheets reviewed

- ✓ All materials and tools laid out

- ✓ Spill cleanup materials ready

During Your Work:

- ✓ Maintaining proper ventilation

- ✓ Following correct mixing ratios

- ✓ Working at appropriate temperature

- ✓ Avoiding skin contact completely

- ✓ Changing gloves if contaminated

- ✓ Taking breaks in fresh air

- ✓ Keeping workspace organized

After Your Session:

- ✓ All tools cleaned properly

- ✓ Waste sorted for proper disposal

- ✓ Workspace surfaces cleaned

- ✓ Contaminated PPE disposed of safely

- ✓ Hands washed thoroughly

- ✓ Ventilation maintained during curing

- ✓ Area secured from unauthorized access

- ✓ Notes made about any issues or exposures

Conclusion

Creating beautiful resin art doesn’t mean compromising your health or safety. Throughout this comprehensive guide to resin art safety and home resin safety, we’ve covered the essential knowledge and practices that allow you to work with these remarkable but hazardous materials responsibly.

While resins offer incredible creative possibilities – from stunning jewelry to magnificent furniture pieces – they remain industrial chemicals that demand unwavering respect and proper handling. The risks are real: chemical burns, respiratory damage, and permanent sensitization are not just theoretical concerns but documented hazards that affect resin artists every day.

However, you can dramatically reduce these risks by implementing the safe resin crafting practices detailed in this guide. Proper PPE, adequate ventilation, careful handling procedures, responsible disposal, and vigilant protection of others in your home aren’t just recommendations – they’re non-negotiable requirements for anyone serious about pursuing resin art safely.

Remember that safety isn’t a one-time consideration but an ongoing commitment. Whenever you open those resin bottles, you either protect or endanger yourself and those around you. By prioritizing safety – wearing that respirator even for “quick” projects, maintaining ventilation throughout curing, and never becoming complacent about protective equipment – you’re ensuring that your resin art journey can continue for years.

Make safety an integral part of your creative process. Your health, your family’s well-being, and your ability to continue creating beautiful art depend on it. Stay safe, create responsibly, and enjoy the wonderful world of resin art with the confidence that comes from doing it right.